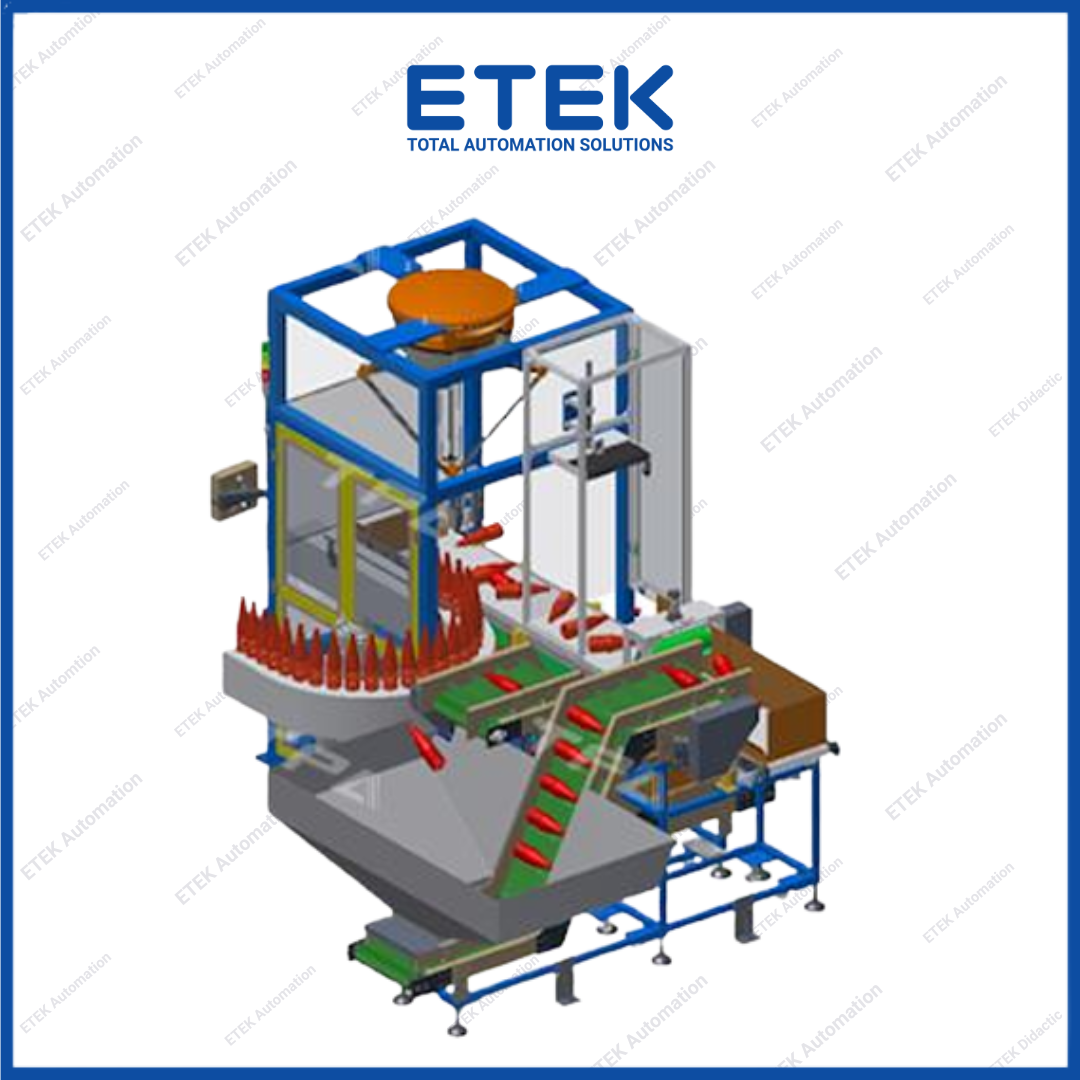

Bottle Unscrambler is an automation solution that helps to arrange and orient the bottle quickly, accurately, optimally for filling and packaging processes. The system uses advanced robot technology, ensuring high speed and flexibility, suitable for many industries such as pharmaceuticals, cosmetics, food and beverages.

Key features of the Bottle Unscrambler system

- High speed, continuous operation – Optimize production time, ensure high performance.

- Precise Orientation – Holds bottles upright, aiding the filling process.

- Increase productivity with block picking technology – Robots can pick up 8×1 bottles at the same time, helping to improve production efficiency.

- Modular Design – Easily expand, adjust or upgrade according to production needs.

Technology applied in Bottle Unscrambler system

- Delta Robot (ABB, Schneider,…) – Picking and sorting bottles at high speed.

- ABB 6-axis robot – Ensures precision and stability during operation.

- Vision System – Automatic product identification and classification, improving accuracy.

- Attack Belt Conveyor – Flexible operation, fast product movement.

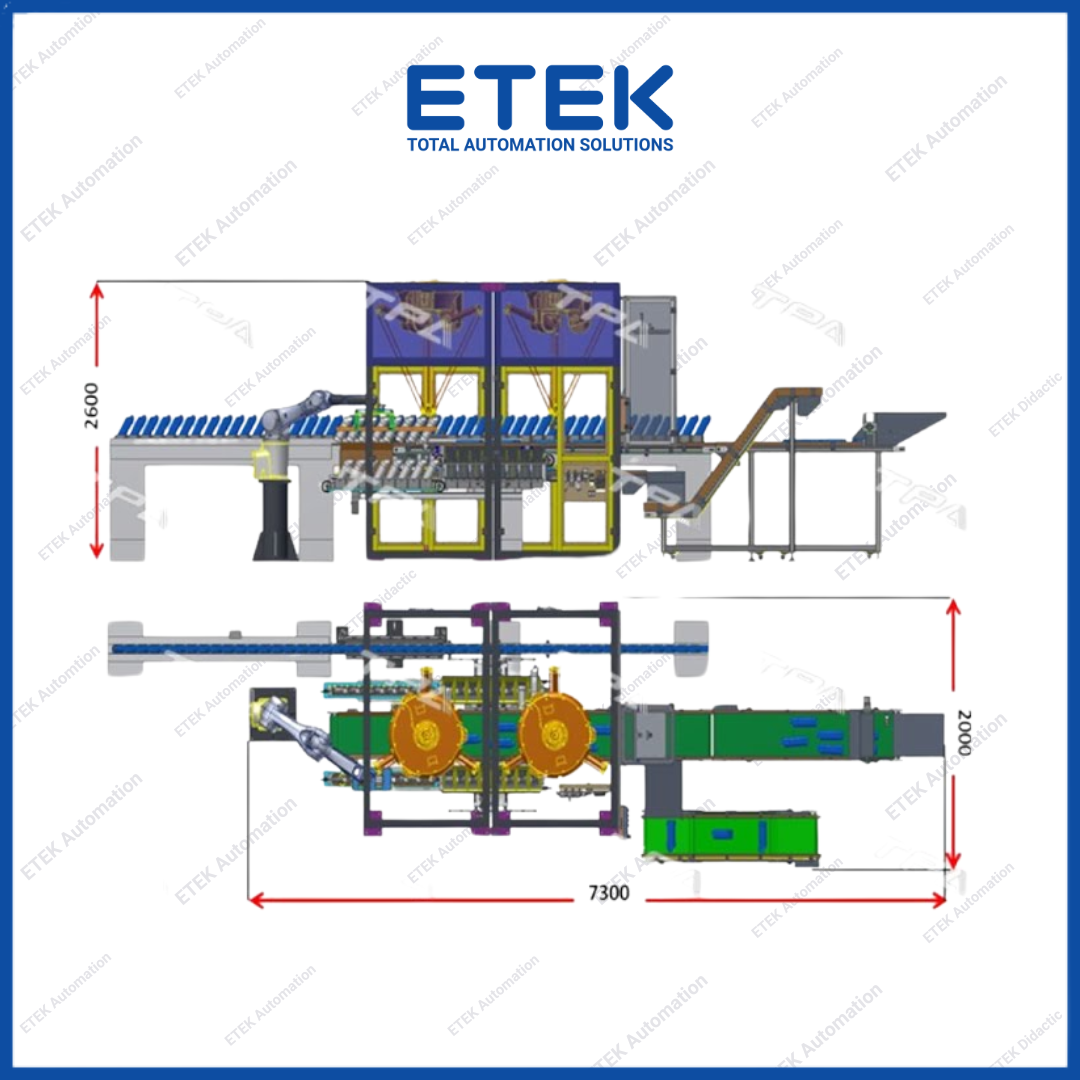

Product specifications

- Size: 7300x2000x2600

- Cycletime: 110 products/minute

- Bottle size: 100x80x30 mm

- Bottle weight: 100g

Application of Bottle Unscrambler system

- Pharmaceutical and Cosmetic Industry

- Food – Chemicals

- dinks

Reviews

There are no reviews yet.