AUTOMATIC CUP NOODLE PACKAGING SOLUTION

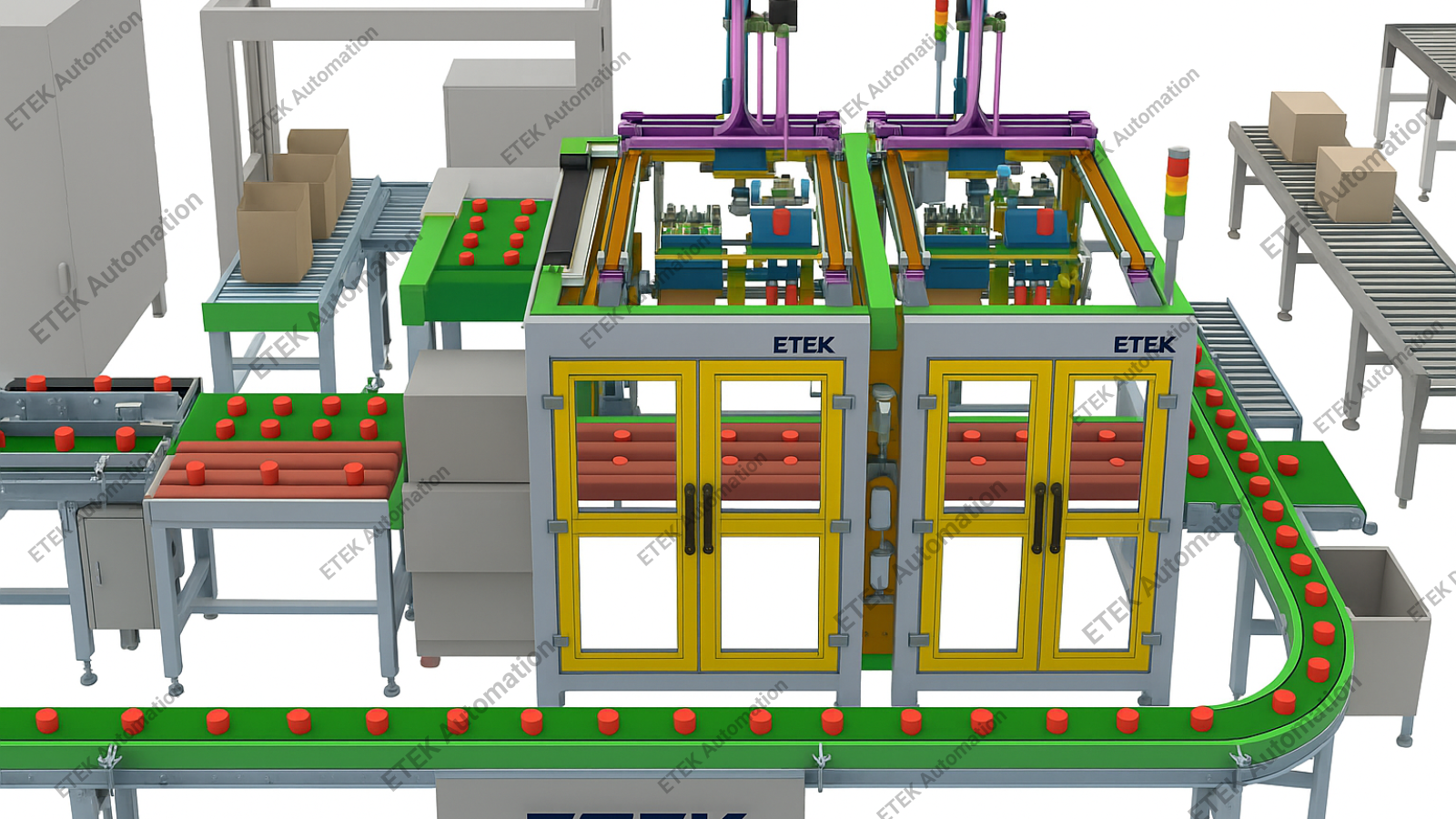

The automatic cup noodle packaging line is a comprehensive solution helping food manufacturers boost productivity, reduce costs, and ensure consistent quality. Utilizing robotic technology, the system fully automates every stage — from feeding and cup flipping to carton erecting and sealing — achieving up to 18,000 cups/hour. Flexible and efficient, it supports various cup-shaped products across the food and FMCG sectors, driving smart and sustainable production.

- Hotline: 0965 800 166

1. Overview

As the instant food industry continues to expand amid intense competition, automation in production and packaging has become an inevitable trend to help businesses enhance productivity, optimize costs, and maintain consistent product quality across all stages.

The automatic cup noodle packaging line is a comprehensive solution that integrates advanced technology with intelligent operational design. It delivers continuous, precise, and flexible performance across multiple product formats. The system enables full automation — from feeding, cup flipping, and bundling to carton erecting, packing, and sealing — meeting large-scale production demands with outstanding efficiency of up to 18,000 cups per hour (2 lines)

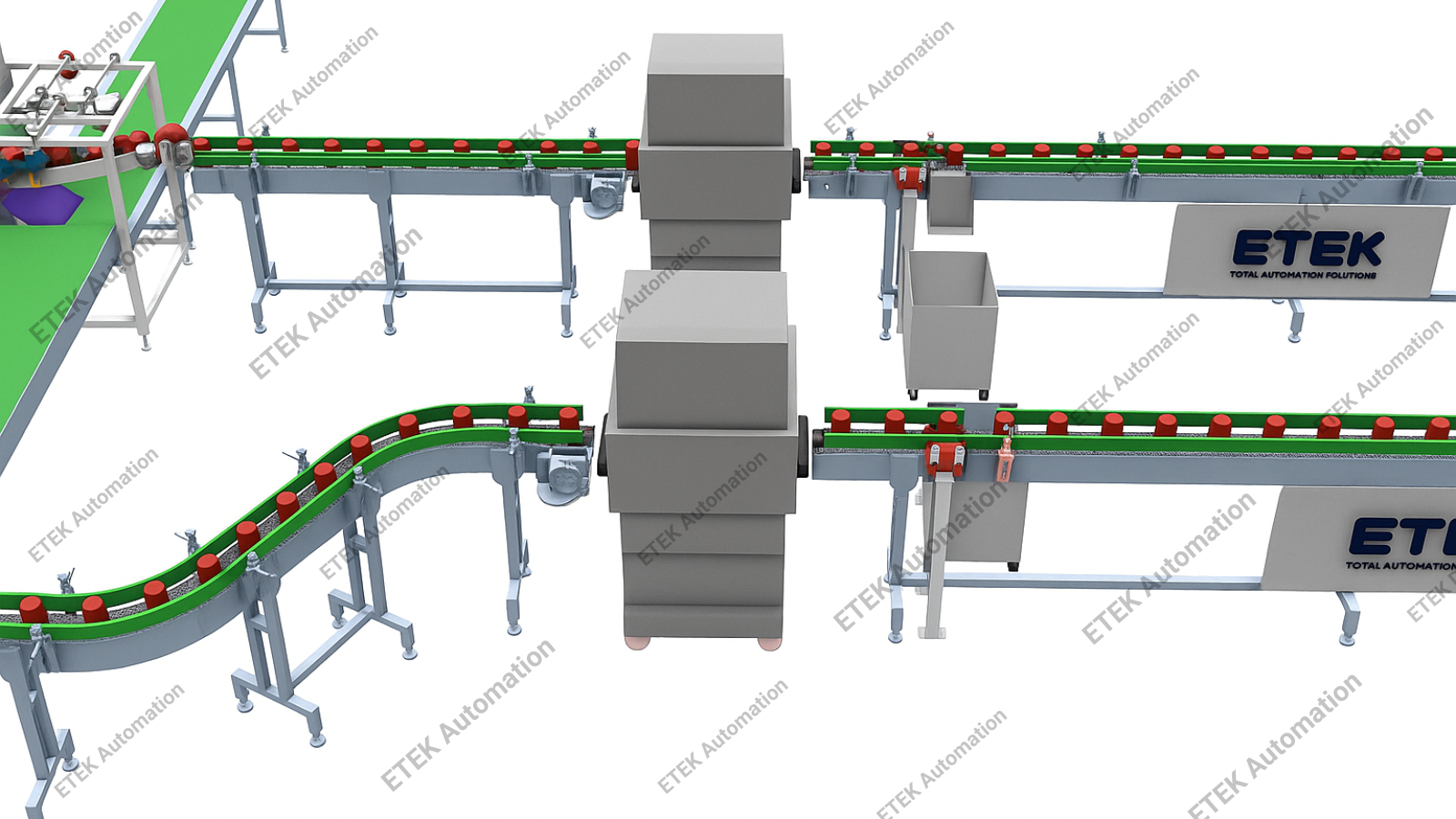

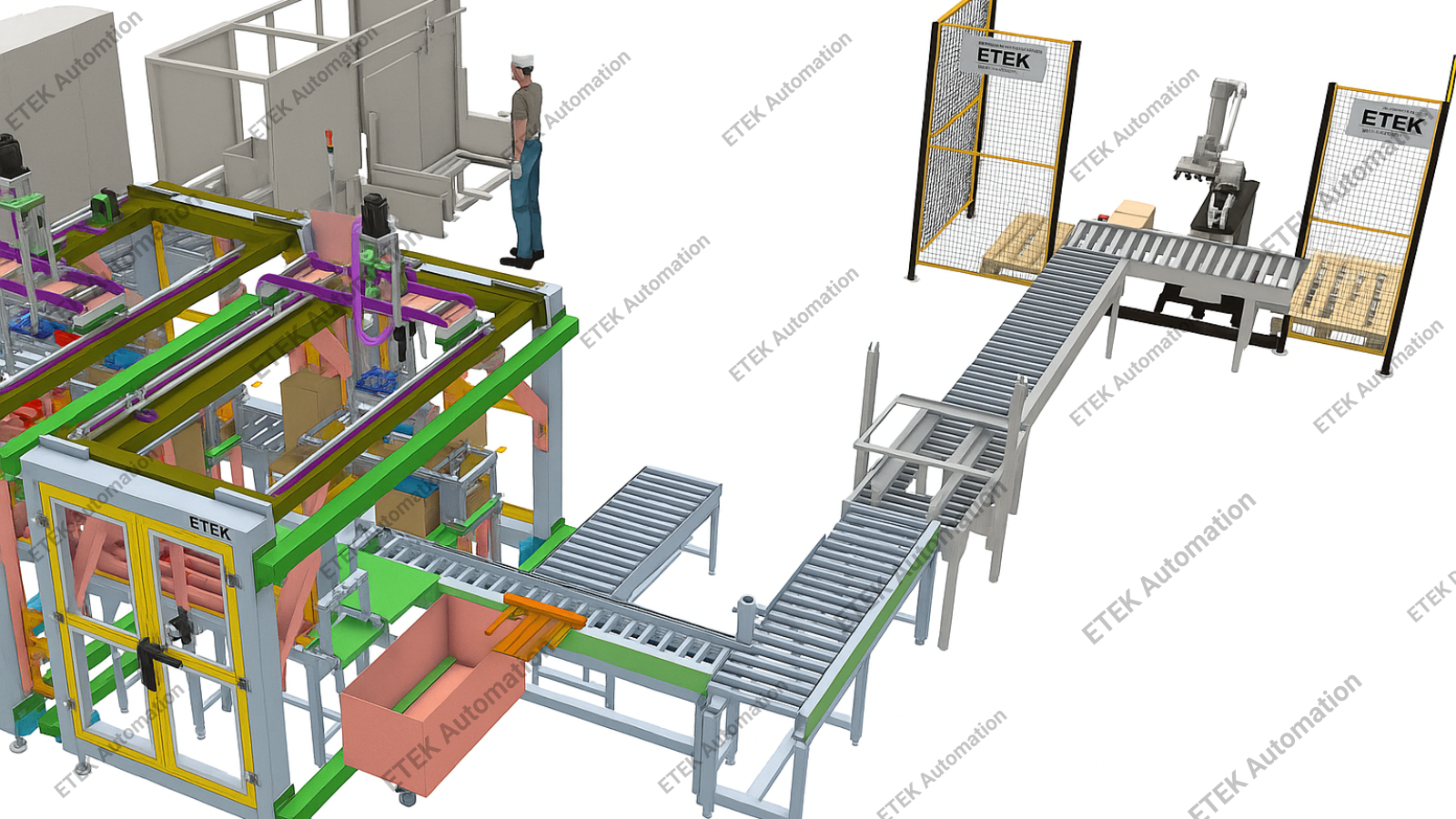

2. Fully Automated and Closed-Loop Operation

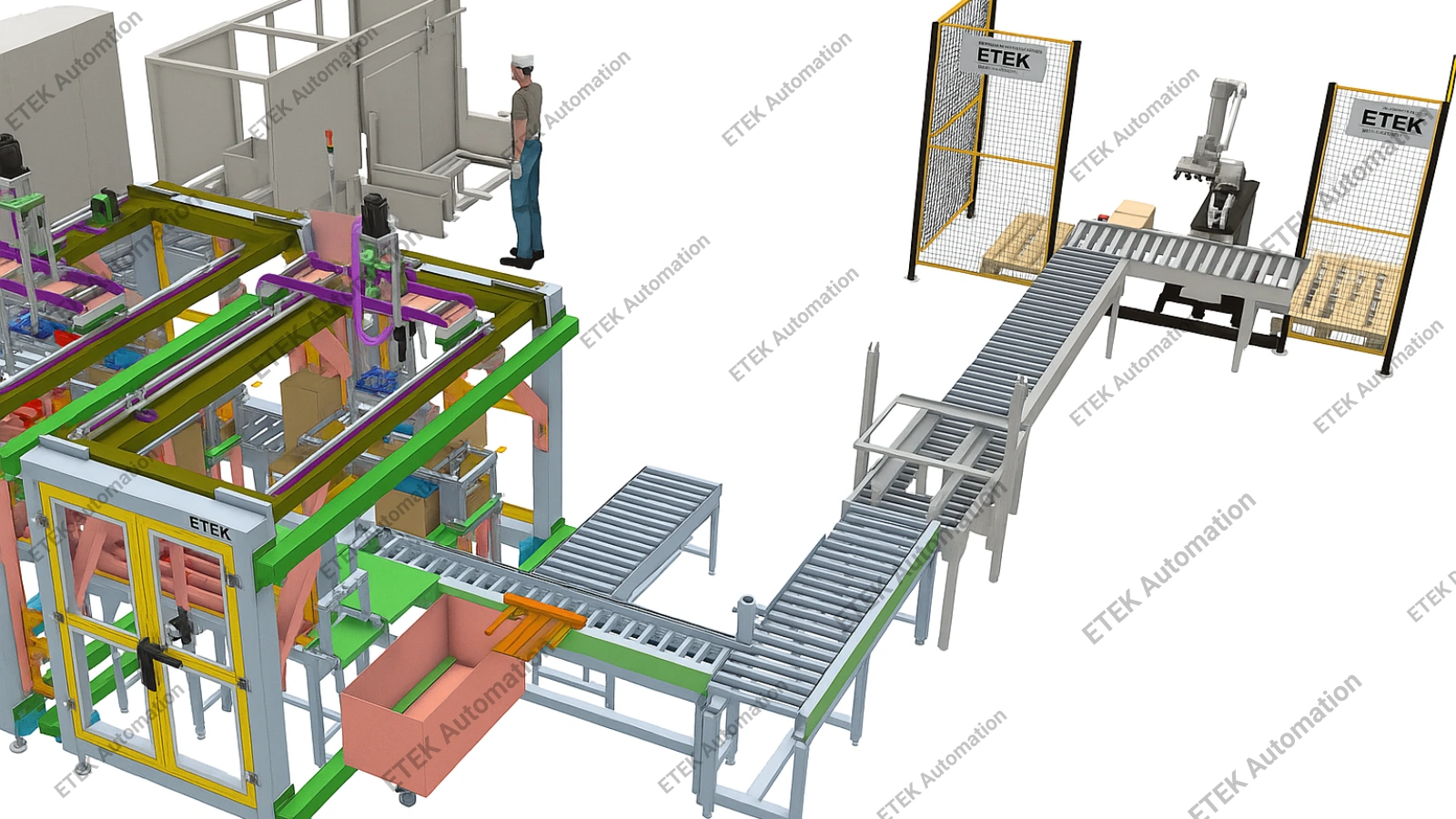

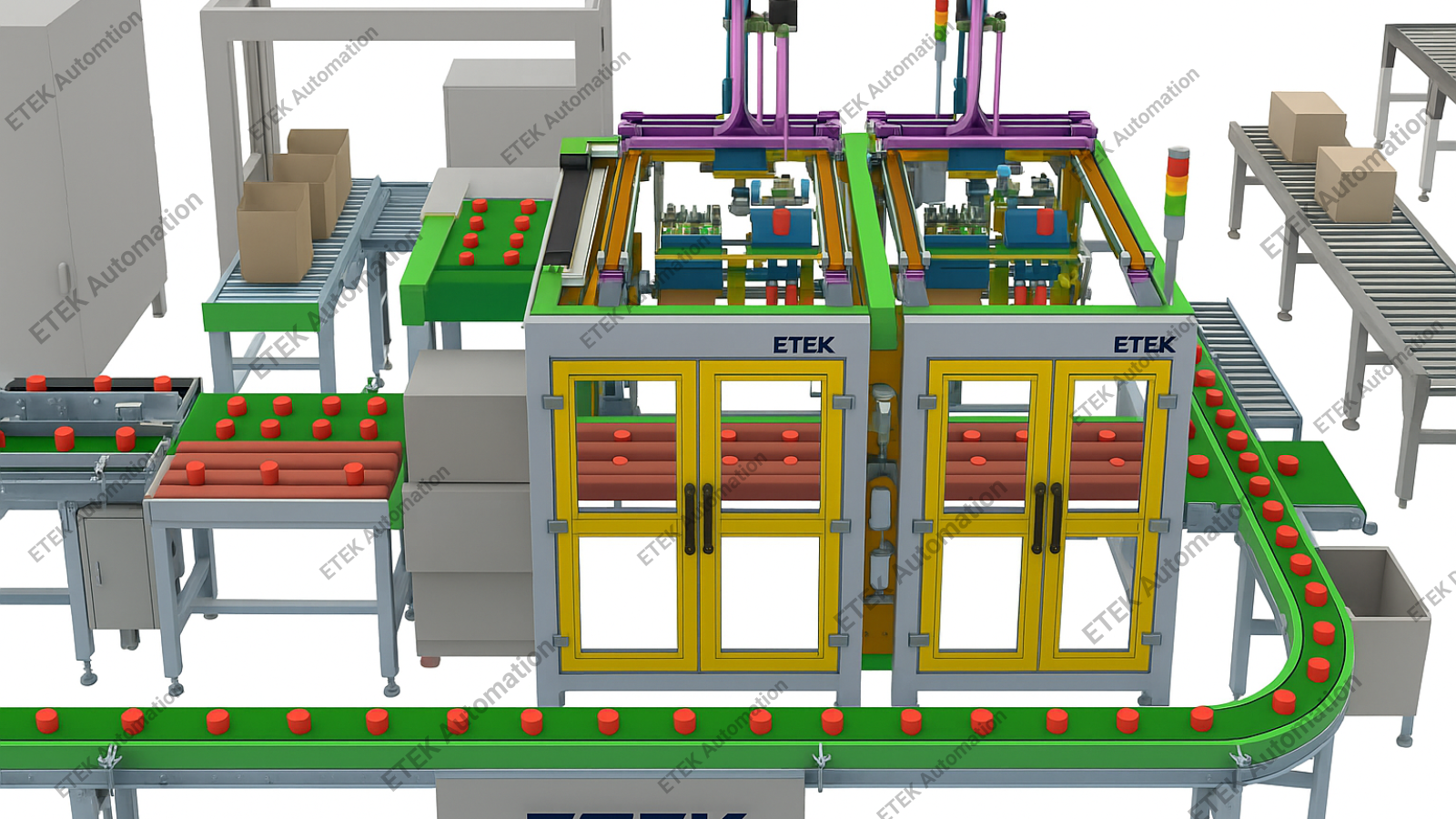

The system is intelligently designed with centralized control via an HMI interface, allowing operators to easily monitor and adjust parameters. The complete system includes:

– Automatic Feeding Station: Provides a consistent and stable product supply for the entire line

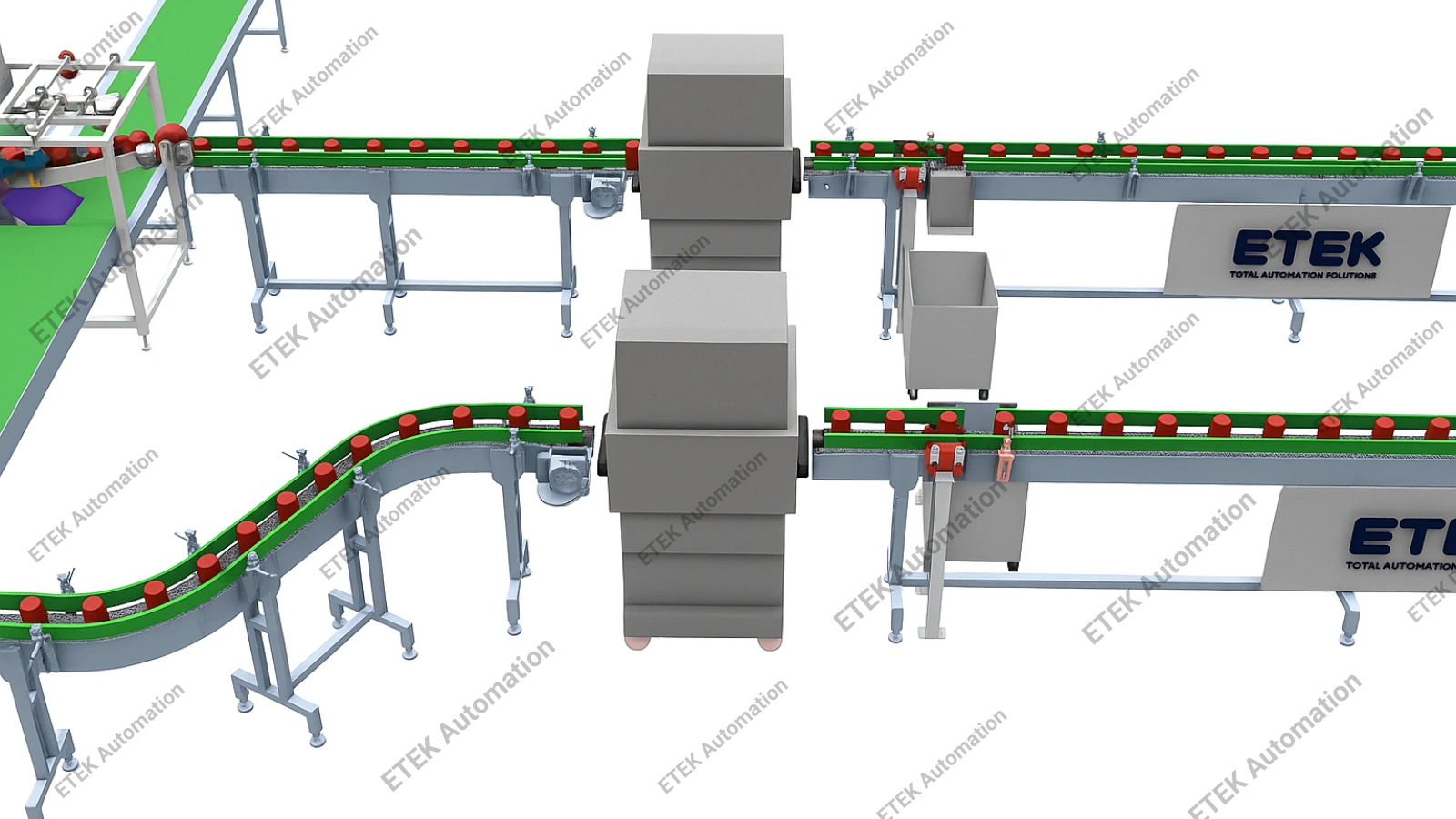

– Lane Divider: Precisely allocates product flow to ensure smooth, continuous operation

– Cup Flipping Station: Utilizes a screw-axis mechanism to alternate cup orientation (up/down) perfectly before bundling

– 4 Lane Distribution Station: Evenly spaces cups on conveyors for optimized bundling and packing

– Gantry Robot for Carton Packing: Employs gantry robot technology with suction tools for accurate, safe, and efficient product placement into cartons

– Automatic Carton Erector and Folder: Forms and folds cartons to predefined dimensions

– Automatic Carton Sealer: Seals carton flaps securely, ensuring aesthetic packaging and safe transport

3. Versatile Applications in Food and Consumer Goods

This solution is ideal not only for instant food packaging (cup noodles, instant porridge, instant pho, etc.) but also adaptable to other cup-shaped products such as plastic cups, paper cups, beverage cups, and similar consumer goods.

Thanks to customizable size and configuration options, the system can be easily integrated into existing production models without major modifications.

4. Key Benefits for Businesses

– Full automation minimizes labor and manual errors

– Outstanding productivity up to 18,000 cups/hour (2 lines)

– Ensures consistent packaging quality that meets export standards

– Flexible operation with easy parameter adjustment via HMI

– Cost-efficient operation and optimized factory space utilization

– High durability and stability, ideal for 24/7 production environments

5. Conclusion

The automatic cup noodle packaging solution marks a significant milestone in the digital transformation and automation journey of the food manufacturing sector. With advanced technology, streamlined design, and exceptional performance, this system empowers businesses to enhance production efficiency, reduce labor costs, and optimize their entire workflow — paving the way toward a modern, intelligent, and sustainable manufacturing line.