Automatic Packaging Solution – Wrap Around Case Packer WWP-RP04

The Wrap Around Case Packer WWP-RP04 is a modern automatic carton packaging solution designed to help businesses increase productivity, reduce costs, and ensure consistent quality. Featuring an intelligent design, advanced PLC control system, and a packing speed of up to 25 cases per minute, the machine perfectly meets the automation needs of food, beverage, and fast-moving consumer goods (FMCG) production lines.

- Hotline: 0965 800 166

1. Overview

In today’s modern manufacturing landscape, automation in packaging lines plays a crucial role in enhancing productivity, optimizing costs, and ensuring consistent product quality.

As a pioneering solution in carton packaging technology, the Wrap Around Case Packer WWP-RP04 is designed to meet high-speed, precise, and stable production demands.

Featuring an intelligent structure, advanced PLC control system, and fully automatic operation, the machine delivers outstanding performance of up to 25 cases per minute, perfectly suited for production lines with capacities of up to 36,000 products per hour—meeting the rigorous standards of food, beverage, and FMCG manufacturing plants.

2. Structure and Operating Principle

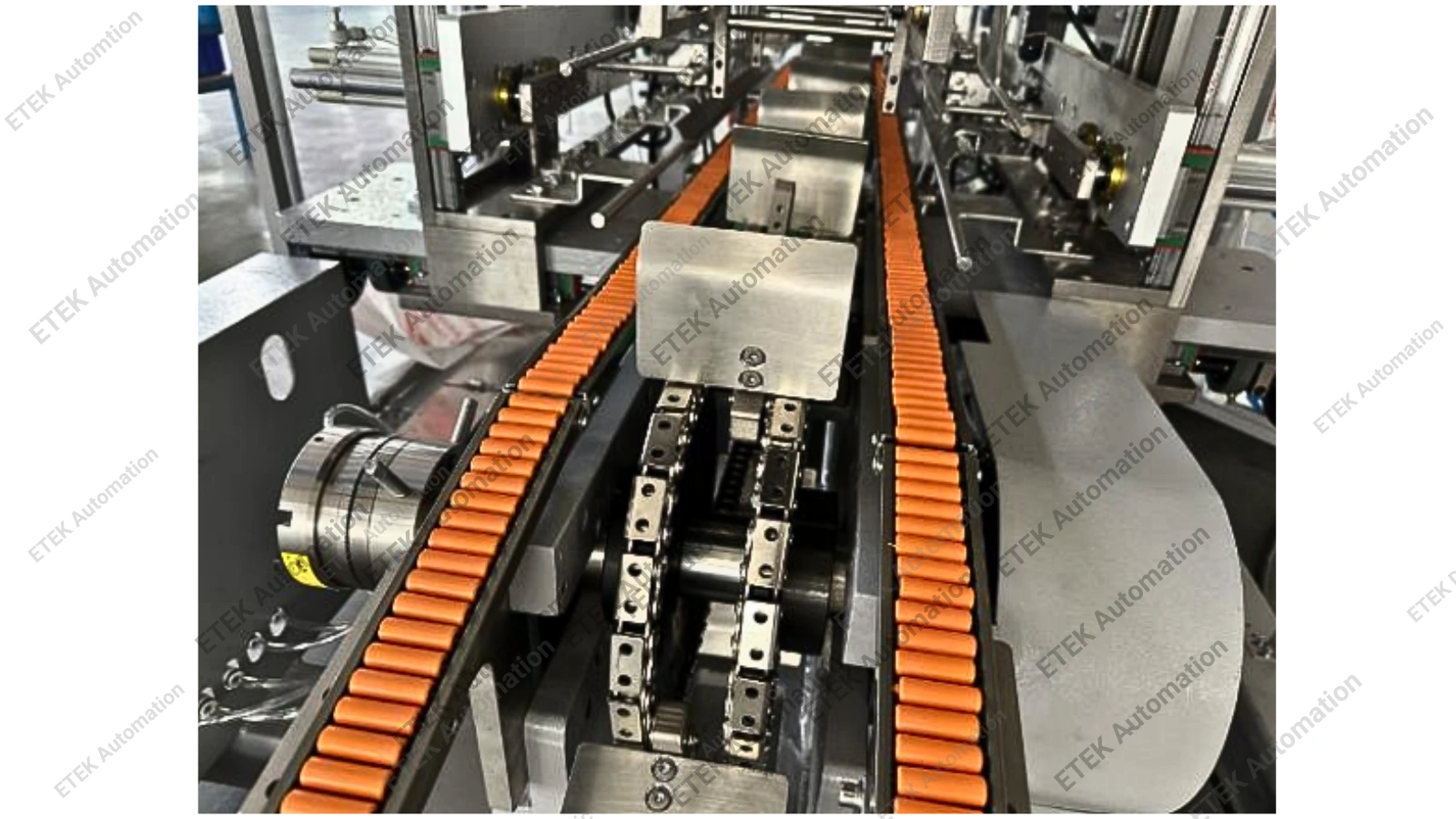

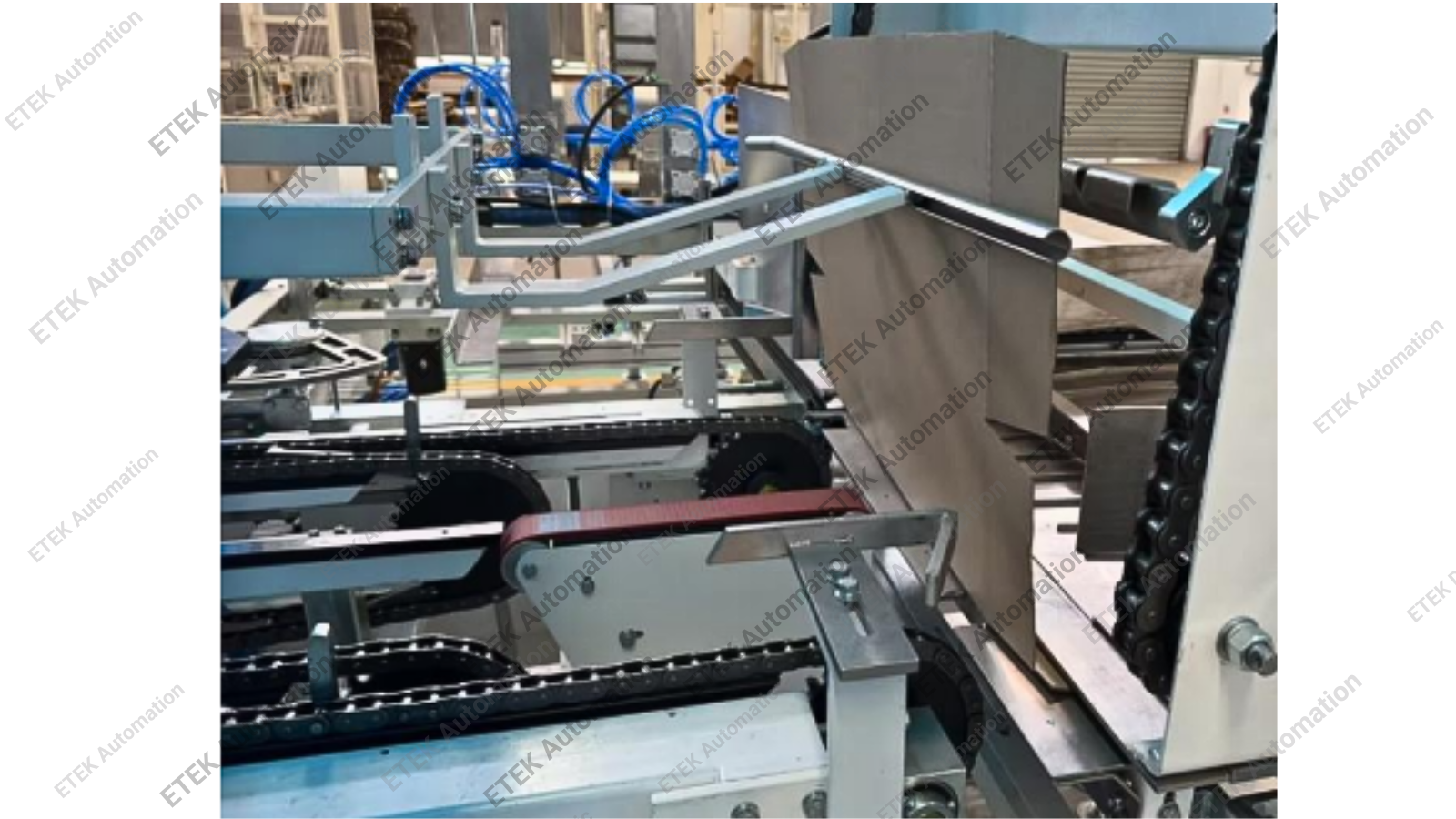

The WWP-RP04 integrates a complete closed-loop packaging process—from product infeed and lane division to carton forming, gluing, and final sealing.

Operating Process:

- The automatic lane divider arranges and separates products evenly into rows.

- The smart conveyor system transfers products smoothly to the packing station.

- The bottle separation and positioning system ensures each product is precisely placed before packing.

- The automatic carton forming unit opens and shapes the wrap-around carton tray.

- The pusher mechanism gently inserts products into the carton in a synchronized motion.

- The Robatech (Switzerland) hot melt gluing unit seals the carton edges securely during movement, ensuring durability and aesthetics.

- The automatic forming and pressing system finalizes the package, delivering a tightly sealed carton ready for output.

3. Technical Specifications

|

Thông số |

Giá trị |

| Model |

WWP-RP04 |

|

Power Supply |

3-phase, 380V, 50Hz |

|

Total Power |

12 kW |

|

Air Pressure |

0.6 MPa |

|

Air Consumption |

500 ml/min |

|

Speed |

25 cases/min |

| Carton Size |

L348 × W234 × H222 mm |

|

Machine Weight |

~4500 kg |

|

Glue Consumption |

~1.8 g/case |

|

Conveyor Height |

1100 mm |

4. Structure and Standard Components

Constructed from Q235 carbon steel with high-quality powder coating, the machine ensures mechanical durability, structural stability, and continuous 24/7 operation.

All components are sourced from world-renowned brands, guaranteeing exceptional reliability:

- PLC, Servo Motors, HMI: Inovance

- Pneumatic Valves & Cylinders: AirTAC

- Sensors & Safety Devices: SICK

- Relay, Contactor, Power Supply: Schneider, Meanwell

- Hot Melt Gluing System: Robatech (Switzerland)

- Linear Guides & Rails: Hiwin

The modular design allows easy assembly, maintenance, and future upgrades—offering flexibility to adapt to evolving production needs.

5. Key Advantages

- Fully Automated Operation: Entire process controlled by PLC, minimizing manual labor and human error

- High Speed & Superior Stability: Reaches up to 25 cases/min with consistent performance

- Precision Engineering: Servo-driven positioning ensures every product is packed accurately

- Compact Design: Seamlessly integrates into existing production layouts without major modifications

- Quick Maintenance: Modular structure enables fast replacement of functional units—minimizing downtime

6. Business Benefits

- Double productivity compared to manual packaging

- Reduced labor and packaging material costs

- Consistent quality across all product batches

- Smart operation monitoring with easy adjustment and maintenance

- Optimized production space, enhancing overall line efficiency

The Wrap Around Case Packer WWP-RP04 is a comprehensive automatic packaging solution that helps businesses increase productivity, reduce costs, and ensure consistent quality. With its intelligent design, stable operation, and high-quality components, the WWP-RP04 perfectly meets the automation needs of the food, beverage, and fast-moving consumer goods (FMCG) industries – an optimal solution for modern production lines.