Smart Packaging Line For Pre-Made Bags

Discover the smart packaging line for pre-made bags, capacity 1200 cartons/hour, helping to increase productivity, reduce costs and optimize factory operations

- Hotline: 0965 800 166

In the context of modern industrialization, smart packaging lines are becoming an indispensable solution to increase productivity and ensure product quality. In particular, packaging lines for pre-made bags with a capacity of up to 1200 cartons/hour have been chosen by many factories to optimize the production process.

Outstanding advantages of smart packaging line for pre-made bags

- High productivity, time saving: With a capacity of 1200 cartons/hour, the line helps the factory complete a large volume of products in a short time, promptly meeting large orders.

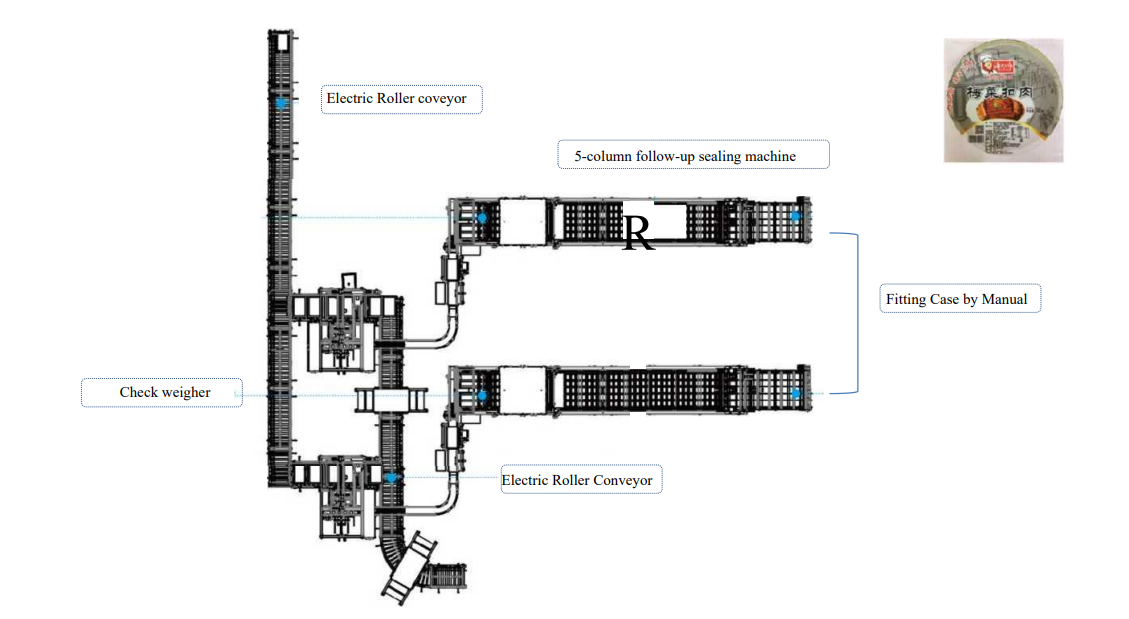

- Semi-automatic automation: The packaging process combines manual carton placement and automated steps such as conveyors and loading robots, helping to reduce labor and increase accuracy.

- Strict quality control: The steps of checking and removing defective boxes are repeated many times during the packaging process, ensuring that only qualified products are fully packaged.

- Flexible in operation: The modular robot frame and electric roller conveyor can be easily adjusted to accommodate different types of containers, making the line operate more efficiently.

Operation process of pre-made bag packaging line

- Manually placing crates onto the storage crate conveyor: Workers place crates into position on the conveyor in preparation for shipping.

- Move bins to lower position: The storage bin conveyor will automatically move the bins to lower position, ready for the next steps.

- Sealing and unloading: The system performs lower carton sealing, then automatically unloads the carton from the conveyor.

- Inspection and removal of defective bins: Quality checks are conducted continuously to remove substandard bins.

- Electric roller conveyor loading and assembly modular robot frame: The robot automatically loads the carton onto the electric roller conveyor for further movement.

- Final inspection and packaging: After final inspection, the product is fully packaged, ready for shipping and storage.

Why choose smart packaging line for pre-made bags?

- Minimize errors during packaging.

- Increase productivity and production efficiency.

- Save manpower and operating costs.

- Easy maintenance and upgrade thanks to modular design.

In short, the smart packaging line for pre-made bags with a capacity of 1200 cartons/hour is the perfect solution to help factories improve production capacity, ensure quality and reduce costs. If you are looking for a modern and efficient packaging system, this is definitely an option not to be missed.