Food

1. Introduction to the Food Industry

The food industry is one of Vietnam’s key economic sectors, experiencing strong growth driven by rising consumer demand and expanding export opportunities. However, alongside these opportunities come major challenges such as food safety, traceability, and operational efficiency in factories.

To meet international standards such as HACCP, ISO 22000, and FDA, many enterprises are gradually adopting automation technology in food production and packaging. This transition not only increases productivity but also ensures consistent product quality while minimizing errors and cross-contamination during manufacturing.

2. The Role of Automation in the Modern Food Industry

Automation enables businesses to optimize their production chain — from filling and packaging to inspection and case sealing.

By implementing intelligent machinery systems, processes become faster, more accurate, and easier to control.

Some key advantages include:

- Ensured hygiene and food safety – Minimized human contact reduces contamination risks.

- Stable product quality – Uniform filling and packaging by volume and weight.

- Increased productivity – Continuous operation with minimal downtime.

- Reduced operating and labor costs – Machines replace most manual tasks.

- Enhanced competitiveness – Enables scale-up and better response to export markets.

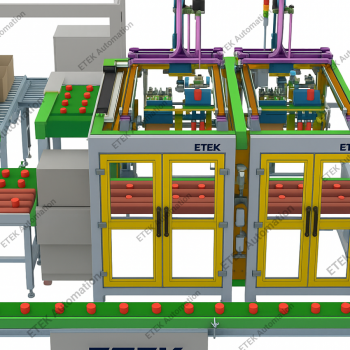

3. Food Packaging Solutions & Equipment Provided by ETEK

At ETEK, we deliver comprehensive filling, packaging, and product-handling solutions for the food industry — suitable for both small-scale producers and large manufacturing plants.

Our range of food industry equipment includes:

- Food filling machines – Using servo piston technology for precise filling of liquids and viscous products such as sauces, cooking oil, milk, honey, and beverages.

- Automatic carton forming machines – Quickly form and seal carton bottoms, saving labor while ensuring stability for final packaging.

- Food packaging machines – Ideal for dry foods, powders, granules, snacks, coffee, confectionery, and instant products.

- Shrink wrapping machines – Protect products from moisture and dust, enhance appearance, and ensure safe transportation.

- Integrated control systems & turnkey production lines – Seamlessly combine multiple devices into a unified process for optimal overall efficiency.

All ETEK equipment is designed and manufactured in compliance with food safety and hygiene standards, using 304 or 316 stainless steel for easy cleaning and bacterial resistance.

4. Key Advantages of Choosing ETEK Solutions

- International compliance: Meet HACCP, ISO, and FDA standards.

- Flexible design: Customizable by size, capacity, or product type.

- Seamless integration: Easily connects to existing factory lines.

- Premium materials: Entire structure and contact parts made of food-grade stainless steel.

- Operational efficiency: Reduce material loss, save energy and labor.

- Professional after-sales service: ETEK offers consulting, maintenance, and operator training packages.

5. Applications in Food Manufacturing Plants

ETEK’s packaging solutions are widely applied across various sectors:

- Beverage industry (pure water, juice, carbonated drinks)

- Canned food, snacks, and confectionery

- Dairy and nutritional products

- Sauces, cooking oil, and seasoning production

- Organic and ready-to-eat food processing

Thanks to their flexibility and precision, ETEK systems help manufacturers upgrade operations, reduce risks, increase competitiveness, and achieve international export standards.

6. Conclusion

With the mission of “Automation for Productivity & Sustainable Food Safety,” ETEK is committed to accompanying food enterprises on their journey toward digital transformation and quality enhancement.

Explore the product list below to learn more about the equipment best suited for your production line.

Our team of ETEK experts is always ready to provide optimized consulting, customized design, and turnkey installation for factories of all sizes.

AUTOMATIC CUP NOODLE PACKAGING SOLUTION

Bag Sealing Machine – APH

Automatic 2 Layer Bag Sealing Machine

Bag Packing Machine – PMW

Automatic Stick Bag Sealing Machine – MLB (4-6 lanes)

Large Bag Sealing Machine

Automatic Granule Bag Packing Machine

Automatic Bag Sealing Machine (Jelly, Gel, Sauce,…)

Bag Sealing Machine – PM150

Automatic Liquid Packaging Machine

Automatic Box Erection Machine